Personal Care Plastic Tube Filling Machine Toothpaste Food Pharmacy Laminated Packaging

| Product Name: | Tube Filling Machine | Speed: | 80 Pieces/min |

|---|---|---|---|

| Filling Accuracy: | +-0.5-1% | Diameter: | 10-50mm |

| After-sales Service Provided: | Online Support | Length: | 50-253mm |

| Packaging Material: | Aluminum, Laminated, Plastic, Composite & Metal Tube | Condition: | New |

| High Light: |

cosmetic tube filling machine, toothpaste filling machine |

||

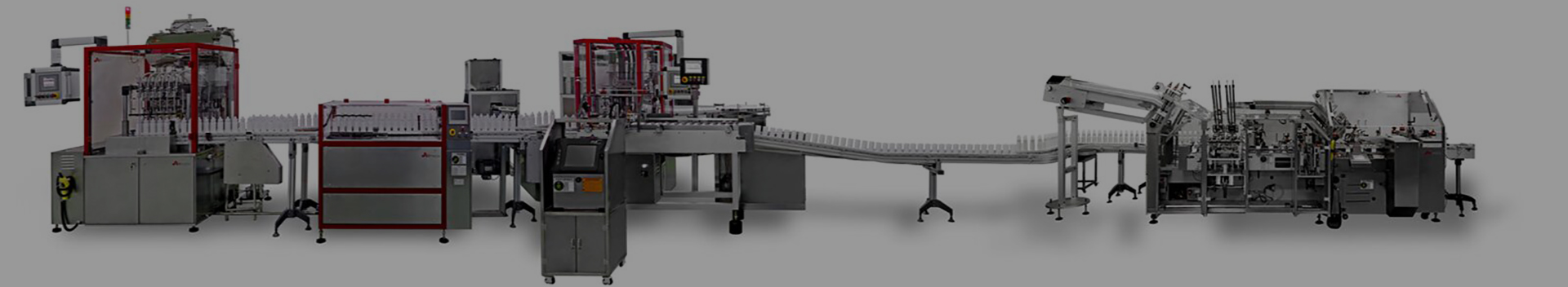

Tube Filing And Sealing Machine For Cosmetic Personnel Care Toothpaste Food Pharmacy Medicine Chemical 80 Pieces/Min

Tube Filling MachineFeatures:

· AT80 tube filling and sealing machine is built with high quality whatever in

material and assembly and tested before shipping

· All the parts contact with products are made of high quality polished SS316

· 12 stations for high capacity output

· Conform with Pharmaceutical GMP Standard

· Fully automatic process from tube feeding to output, no artificial contamination

· Siemens PLC and Delta Touch Screen for easy operation

· Piston pump for easy control the fluid filling amount

· Filling accuracy error: < ±0.5 % of volume

· Special Patent Design Hot Gun sealing technology

· Banner photoelectric sensor for high precision track positioning

· Single or dual sided date coding and batch number

· Output: up to 3,600 tubes / hour

· Available with all plastic and laminated tubes and metallic aluminum tubes

Tube Filling MachineAdvantages:

· AT80 tube filling and sealing machine use cam drive as driving system. The cam process with 38 RMOAL treatment, make it solid and durable to ensure long life driving

· Use Hot Gun Heating System, patent design, the sealing is stronger, faster, more even than regular heating tube system

· Use continuously Variable Transmission Inverter to ensure the high output capacity with stable performance

· Use full closed bearing system for mechanical arm, use linear bearing for other slide shafts, to ensure oiless operation, keep the product high standard

· Two individual fluid cutting off system on the filling head station, especially add an extra air blow off system on the filling head station, ensure the machine clean operation even with high viscous fluid

· Add a bearing in the tube feeding station, make sure the feeding process smooth.

· Use cylinder to push the tubes down to the bottom, ensure they are in even position, reduce the failure rate

· Use a pulse system for photoelectric marking, improve the stability

· Intelligent failure rejecting system, it will kick out the empty tube

Key features of the tube filling and sealing machine:

• The tube filling and sealing machine is made of high quality stainless steel

• All elements having contact with product are made of high quality stainless steel

• Electronic control of sealing parameters and process with saving option

• Filling accuracy error: < ±1 % of volume

• Hot air sealing technology

• Single or dual sided coding with set of fonts included

• Works with all plastic and laminated tubes

Tube Filling Machine Details:

![]()

Tube Filling MachineApplications:

| Personnel care | Cosmetic, shaving, liquid soap, skin & sun care, hair care, other personnel care, toothpaste |

| Other industry |

Chemistry, food, pharmacy and etc. |

Competitive Advantage:

Stable, reliable and high quality machine which need less service. Very short product and size change over with precise filling accuracy. Easy operate with Siemens HMI providing English, Chinese or other language that is on request. Designed to fill and close all type of tubes available on the market with perfect respect for the product.